[ad_1]

Do you need clarification about the uses and advantages of the 6-point and 12-point sockets? Is it difficult to figure out which one is suitable for you? Well, then, you have landed yourself in the right place. In this article, we have discussed which tool is better suited for your function.

Using the 6-point tool with the 6-point fastener and the 12-point tool with the 12-point fastener will increase the steel contact and reduce the probability of the toll breaking or slipping. This is particularly important when the fastener is broken or rusty. Let us now get to the discussion of each of the

What is a 6-Point Socket?

The 6-point socket features drilled-out corners. The pressure for this is applied to the shoulder of the point. In this, the nut is connected directly to the point of the bolt. It is easy-to-install, and the process is quick and easy. It is better suited for the rounded-off nuts requiring a greater surface point.

Uses of a 6-Point Socket

There are several uses for 6-point sockets. They are listed below.

- They are suitable for high-intense force applications.

- Better for the secondary contact faucet which is unlikely to slide with the level gauge edges.

- Features broader walls which maximizes the strength.

- Works well with the 6-point fasteners.

Pros and Cons of a 6-Point Socket

In this section, we will see the advantages and disadvantages that are offered by the 6-point socket. It will help you choose better according to your requirements.

Advantages

- They are more suited for tasks that require greater force. So, it is most likely that the impact sockets are always available in the 6-point configuration for all the right reasons.

- The greater contact area makes them less likely to slip in the corners or strip the bolt.

- The thicker wall of the 6-point socket enables them to prevent slipping or flexing.

- The thicker walls also imply that they are less likely to break under unfavorable circumstances.

Disadvantages

- It is not ideal for small or limited spaces.

- The 6-point sockets are not an option to be used with the 12-point bolts.

What is a 12-Point Socket?

On the other hand, the 12-point sockets are better for areas with limited space with a shorter throw and restricted space to move the ratchet handle. So, these points are better if you are looking for a convenient connection in some hard-to-reach and hard-to-see spaces. They enable you to attach fasteners at difficult angles.

Uses of a 12-Point Socket

We will discuss the uses of the 12-point socket:

- They are highly suitable for tight areas and ratchets with multiple teeth.

- Great for removing locking wheel nuts.

- It has easier installation and saves time.

- Fits easily even when tapped gently.

Pros and Cons of a 12-Point Socket

Now, we will look at the advantages and disadvantages offered by the 12-point socket. It will give you a clearer view of the socket.

Advantages

- The extra “notches” in the 12-point socket make it more convenient to install and save time for the user.

- It features a better range of motion, allowing you to connect at more angles. This makes it better for areas with limited spaces.

- It is necessary to use a 12-point socket for a 12-point fastener.

Disadvantages

- The hexagonal bolts will likely be stripped with the 12-point sockets.

Differences Between a 6-Point and a 12-Point Socket

| 6-Point | Vs | 12-Point |

| Thicker Wall.

Increases Contact on 6-Point Bolts. |

Design | Thinner Wall

Less Contact on 6-Point Fasteners |

| Higher Torque Resistance

Less Likely to Damage Over Time. |

Strength | Less Torque Resistance.

Round-off Fasteners Can be Shattered Easily. |

| 6-Point Fasteners | Used on | 6-Point and 12-point Fasteners. |

| Slightly More Difficult to Connect With Fasteners. | Connection | Easier to Connect With Bolts |

| 99% DIY Tasks | Application | Ch Spots Used for Hard-to-see and Hard-to-Rea. |

After getting a clear view of the 6-point and the 12-point fasteners, this section will allow you a clearer view of the differences between the 6-point and the 12-point sockets.

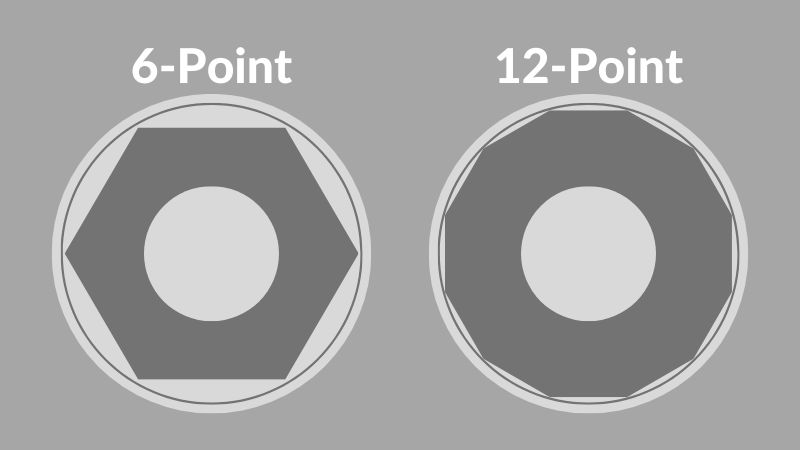

1. Design

This is a huge point of difference between the two sockets. The 6-point sockets feature thick walls with hexagonal contact points. They also have a wider surface area for less slip and better grip. The high torque tasks are made possible with the robust structure. On the contrary, the 12-point sockets have double hexagonal contact points, ensuring easier installation. They feature thinner walls making them easier to break. Also, they have a smaller contact area compared to the 6-point sockets.

2. Torque Transfer

To understand torque transfer, you need to look at the requirements and the bolts you are working with. In most cases, you will be encountering the 6-point bolts. These bolts transfer more torque due to a higher contact area and a thicker wall structure. So, this makes the 12-point structure more likely to slip when handling high pressure. However, you need to know that the 12-point bolts only fit 12-point sockets.

3. Application

For a DIYer, the 6-point sockets are the perfect sockets. However, the 12-point sockets are better suited for certain tasks as they can be installed more easily. They are also ideal for tighter spaces.

Which Socket Should I Choose, a 6-Point or a 12-Point Socket?

| Application | 6-Point | 12-Point |

| With Long Handles | ❌ | ✅ |

| In Limited Spaces | ❌ | ✅ |

| When Dealing With Greater Force | ✅ | ❌ |

| Lower Potential for Stripping a Bolt Head | ✅ | ❌ |

The 6-point and the 12-point sockets can be used interchangeably for most requirements, but sometimes one is preferred over the other. So, the 6-point sockets are more suited for force-intensive or high-impact applications. Their properties of lower potential for stripping the bolt head and wear resistance make them more suited for these circumstances.

On the other hand, if much force is not required, you should go for the 12-point sockets in case of smaller areas. They are better suited for ratchets with multiple heads. Also, it is necessary to remember that 12-point bolts exclusively need 12-point sockets to work.

Final Word

To summarize, we think the 6-point sockets are better for removing all sorts of fasteners that may be jammed or rusted. Also, they are better options when working with high torque. Or else, the 12-point sockets can work just fine. We have listed everything you need to know about 6-point and 12-point sockets.

If you still have doubts or any kind of suggestion, do mention in the comments section below.

[ad_2]